Plastic Granules Mixer Machine

Price 195000 INR/ Set

MOQ : 1 Set

Plastic Granules Mixer Machine Specification

- Type

- Plastic Granules Mixer Machine

- Material

- Mild Steel (MS) Body with Stainless Steel Mixing Chamber

- Capacity

- 100 kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Panel Based

- Drive Type

- Electric Motor

- Screw Diameter

- Customizable (Standard: 55 mm)

- Power

- 5 HP

- Weight (kg)

- 450 kg

- Dimension (L*W*H)

- 1500 mm x 850 mm x 1800 mm

- Color

- Sky Blue & Grey

About Plastic Granules Mixer Machine

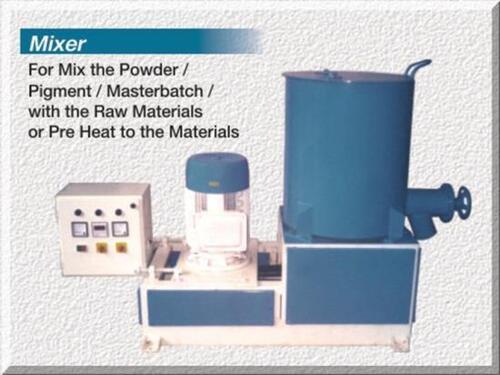

The Plastic Granules Mixer Machine is a special, highly recommended asset for plastic processing units requiring first-class mixing performance. With an unassailable 8-10 minute mixing time per batch, this distinguished machine seamlessly blends plastic granules, masterbatch, and additives. Powered by a robust 5 HP electric motor and operating at 110 RPM, it features a spacious 150L stainless steel mixing chamber with a corrosion-resistant mild steel body. Its bottom discharge with pneumatic valve ensures easy unloading, while heavy-duty castor wheels provide effortless mobility. This semi-automatic mixer boasts a distinguished control panel, customizable screw diameter, and ultra-quiet operation below 70 dB. Get this premium solution as an exporter, manufacturer, or supplier in India.

Used For, Features & Primary Competitive Advantages

The Plastic Granules Mixer Machine is used for preparing homogeneous mixtures of plastic granules, masterbatch, and additives in various plastic processing units. Key features include a 150-litre stainless steel mixing chamber, bottom pneumatic discharge, sky blue & grey finish, and panel-based control. Its corrosion resistance, semi-automatic operation, and heavy-duty castor wheels set it apart. The mixer's primary competitive advantage lies in its efficient cycle time, robust build, low noise output, and ease of mobility, making it a highly desirable choice.

Delivery Time, Supply Ability & Main Export Market(s)

Expect prompt quotation issuance and reliable drop-off services when ordering the Plastic Granules Mixer Machine. Shipped goods are handled efficiently to ensure on-time delivery, maintaining the integrity of each 450 kg unit. With strong supply ability, the exporter confidently meets both large and small orders for domestic and international clients. Major export markets include Asia, Africa, and the Middle East, offering first-class support and distinguished after-sales service to all clientele.

Used For, Features & Primary Competitive Advantages

The Plastic Granules Mixer Machine is used for preparing homogeneous mixtures of plastic granules, masterbatch, and additives in various plastic processing units. Key features include a 150-litre stainless steel mixing chamber, bottom pneumatic discharge, sky blue & grey finish, and panel-based control. Its corrosion resistance, semi-automatic operation, and heavy-duty castor wheels set it apart. The mixer's primary competitive advantage lies in its efficient cycle time, robust build, low noise output, and ease of mobility, making it a highly desirable choice.

Delivery Time, Supply Ability & Main Export Market(s)

Expect prompt quotation issuance and reliable drop-off services when ordering the Plastic Granules Mixer Machine. Shipped goods are handled efficiently to ensure on-time delivery, maintaining the integrity of each 450 kg unit. With strong supply ability, the exporter confidently meets both large and small orders for domestic and international clients. Major export markets include Asia, Africa, and the Middle East, offering first-class support and distinguished after-sales service to all clientele.

FAQ's of Plastic Granules Mixer Machine:

Q: How does the Plastic Granules Mixer Machine ensure homogeneous mixing?

A: The machine is equipped with a stainless steel mixing chamber, optimized rotation speed of 110 RPM, and a bottom discharge with a pneumatic valve which collectively create consistent, thorough blending of plastic granules, masterbatch, and additives for homogeneous output every batch.Q: What are the benefits of using a semi-automatic mixer in plastic processing?

A: A semi-automatic mixer combines operational ease with precise panel-based controls. This blend offers higher productivity, reduced human error, improved mixing quality, and minimized energy consumption-delivering significant value for plastic processing units.Q: Where can the Plastic Granules Mixer Machine be installed for maximum efficiency?

A: This machine is best suited for plastic production facilities, manufacturing plants, and processing units where efficient, high-capacity mixing is essential. Its heavy-duty castor wheels ensure easy relocation within your workspace for optimal workflow arrangement.Q: When can I expect my shipment after placing a quotation?

A: Upon receipt and approval of your quotation request, the machine is shipped promptly with typical drop-off timelines depending on your location. Our team provides precise delivery schedules and ensures goods reach you efficiently.Q: What customization options are available for the screw diameter?

A: The mixer offers a standard screw diameter of 55 mm, but customization can be provided upon request to meet unique blending requirements, enhancing process adaptability and output quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

JVM PLASTOMECH

GST : 24ABTPJ5567H1Z7

GST : 24ABTPJ5567H1Z7

18, Harikrupa Industrial Estate, Kathwada GIDC Road No. 5, Kathwada,Ahmedabad - 382430, Gujarat, India

Phone :08045802148

|

|

JVM PLASTOMECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry