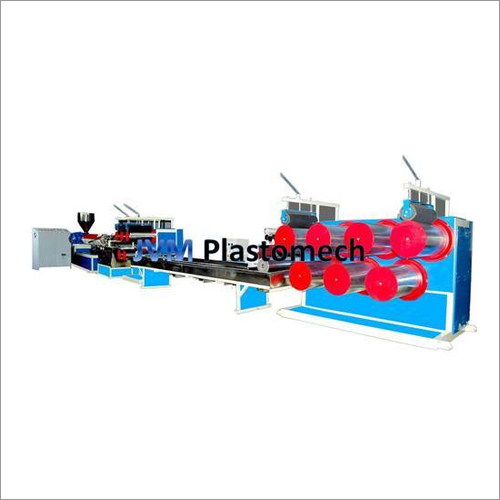

HDPE Monofilament Plant

Price 2851000 INR/ Unit

HDPE Monofilament Plant Specification

- Model No

- HDPE-MONO-300

- Usage & Applications

- Yarn making, Monofilament thread, Brush Industry, Fishing Net, Agro Shade Net

- Motor Power

- 30 HP

- Driven Type

- Electric

- Production Capacity

- Up to 300 kg/hr

- Efficiency (%)

- 92%

- Source

- Manufacturer

- Plastic Processed

- HDPE, PP

- Accessories

- Spinning die, Take up unit, Water bath, Dancer unit

- Automation Grade

- Fully Automatic

- Frequency

- 50/60 Hz

- Speed

- 60-120 m/min

- Temperature Range

- 30C - 300C

- Installation Guideline

- On-site technical support provided

- Type

- HDPE Monofilament Plant

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Controlled

- Drive Type

- AC Drive

- Voltage

- 440 V

- Weight (kg)

- 3500 kg

- Dimension (L*W*H)

- 6500 x 1800 x 2200 mm

- Color

- Blue / White

- Capacity

- 50-300 kg/hr

- Surface Finish

- Powder Coated

- Machine Type

- Monofilament Extrusion Machine

- Power Consumption

- Approx. 38 kW/hr

HDPE Monofilament Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About HDPE Monofilament Plant

HDPE Monofilament Plant is capable of extrusion of yarns of different thicknesses. It works at very high speed and its design is suitable to harsh and adverse conditions of the industry. This plant is manufactured by our skilled professionals using modern technology and top notch quality components in line with industry standards. It consumes less electricity and can work for longer duration of time without any hassle. Rendering smooth operation, this HDPE Monofilament Plant is available in different designs and sizes to meet various demands of our clients.

Product details

|

Color |

Blue & White |

|

Capacity |

55 - 80 Kg/Hr |

|

Machine Type |

Semi-Automatic |

|

Power Consumption |

25 HP |

|

Usage/Application |

Yarn Making |

|

Brand |

JVM |

Advanced Extrusion Technology

This monofilament plant is equipped with a precision-engineered 55 mm extruder screw and a 30: 1 L/D ratio, ensuring uniform melt and superior filament quality. The PLC-controlled, fully automatic setup includes a PID controller for precise process management and energy efficiency, while the integrated pre-heater and ceramic band heaters ensure optimal extrusion temperatures.

High Output & Versatility

Capable of producing up to 300 kg/hr of monofilament with a diameter range of 0.15 to 1.2 mm, this plant accommodates both virgin HDPE and PP granules. With adjustable line speeds from 60 to 120 m/min via VFD, it is ideal for small to large-scale operations in industries such as brush manufacturing, fishing nets, and agro shade nets.

User-Friendly Operation & Safety

An intuitive digital touch screen display simplifies operation, while robust safety measures include overload/short circuit protection, emergency stops, guards, and safety interlocks. Changeover and maintenance are facilitated by a fine mesh, easily replaceable filtration system and centralized lubrication, promoting uptime and worker safety.

Comprehensive Service & Support

Backed by a 15+ year economic lifespan and extended AMC, the plant includes comprehensive 24x7 online and offline service support. Installation guidelines are provided, including onsite technical assistance to ensure smooth setup on a level floor with a 3-phase power supply. Accessories such as a spinning die and take-up units are included.

FAQs of HDPE Monofilament Plant:

Q: How does the HDPE Monofilament Plant ensure consistent filament quality?

A: The plant utilizes a high precision monofilament die head, controlled PID process, and ceramic band heaters across four heating zones for stable temperature. The integrated pre-heater and centralized lubrication system further enhance consistency, resulting in uniform and high-quality monofilaments.Q: What are the primary applications of the HDPE-MONO-300 monofilament extrusion machine?

A: This plant is designed for manufacturing monofilament yarn and threads used in various industries such as brush manufacturing, fishing nets, agro shade nets, and other industrial yarn applications. Its capability to process both HDPE and PP granules adds to its versatility.Q: When is service support available for this monofilament plant, and what kind of after-sales assistance is provided?

A: Comprehensive 24x7 online and offline support is available for troubleshooting, spares, and maintenance. Extended Annual Maintenance Contracts (AMC) can be availed for scheduled servicing and technical assistance, ensuring long-term operational reliability.Q: Where can the HDPE Monofilament Plant be installed, and what are the pre-installation requirements?

A: The plant is suitable for installation in small to large scale industrial settings where the ambient temperature is between 5C to 45C. Pre-installation requires a level foundation, access to a 3-phase 440V power supply, and proper ventilation for safe and efficient operation.Q: What benefits does the automatic grade and computerized (PLC) control system offer?

A: Automatic and PLC-controlled operations provide easy set-up and monitoring via a digital touch screen, enabling precise speed adjustments, consistent product quality, and safe process management, leading to reduced labor costs and minimized operator intervention.Q: How is safety ensured during plant operation?

A: Safety is prioritized with multiple features including emergency stop, safety guards, interlocks, electrical overload and short circuit protections, and a noise level maintained below 80 dB to enhance workplace safety.Q: What is the typical economic lifespan of the HDPE-MONO-300 plant, and how energy efficient is it?

A: Engineered for durability with a lifespan of over 15 years, the plant incorporates energy-efficient technologies such as AC VFD drives, fine mesh filtration, and optimized heating to maintain an approximate power consumption of 38 kW/hr, delivering high efficiency (up to 92%%) and reduced operating costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP HDPE Monofilament Plant Category

Monofilament Plant

Price 2251000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 440 V

Surface Finish : Other, Powder Coated

Capacity : 50300 kg/hr

Weight (kg) : 2500 kg

GST : 24ABTPJ5567H1Z7

|

|

JVM PLASTOMECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry