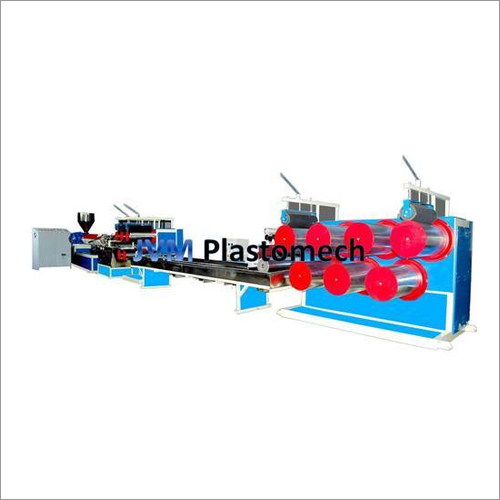

Monofilament Plant

Price 2251000 INR/ Unit

Monofilament Plant Specification

- Frequency

- 50 Hz

- Accessories

- Hopper Loader, Water Bath, Winder Unit, Cutter, Air Compressor

- Driven Type

- Gear Drive

- Efficiency (%)

- 95%

- Source

- Manufacturer Direct

- Motor Power

- 30 HP

- Temperature Range

- 50C - 300C

- Automation Grade

- Fully Automatic

- Plastic Processed

- PP (Polypropylene), HDPE

- Installation Guideline

- Installation Manual Provided

- Production Capacity

- 200 kg/hr

- Speed

- 60-200 m/min

- Usage & Applications

- Manufacturing of Monofilament Yarn, Plastic Fencing, Net, Sutli, etc.

- Model No

- MF-2024

- Type

- Monofilament Plant

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Control Panel

- Drive Type

- Electric

- Voltage

- 440 V

- Weight (kg)

- 2500 kg

- Dimension (L*W*H)

- 5000 mm x 1200 mm x 2000 mm

- Capacity

- 50-300 kg/hr

- Power Consumption

- 35 kW

- Machine Type

- Monofilament Extrusion Machine

- Surface Finish

- Powder Coated

Monofilament Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Monofilament Plant

Our provided range of PET Monofilament Plant is a highly reliable option to produce superior quality of monofilament Yarn which are then applied to make plastic ropes, brushers, nets, mesh used in surgery, and many more products. It is manufactured from superior quality machine components with the aid of state of the art technology.It is highly demanded by our patrons for its attributes such as hassle free performance, optimum quality and rugged construction.Moreover, we are offering this PET Monofilament Plant in different specifications to our patrons at leading market rates.

Product details

|

Phase |

3 Phase |

|

Usage/Application |

PET Bristel Making |

|

Material |

PET |

|

Frequency |

AC |

|

Voltage |

440 V |

|

Color |

Blue & White |

|

Machine Type |

Semi-Automatic |

|

Capacity |

80 Kg/Hr |

|

Brand |

JVM |

Advanced Monofilament Extrusion Technology

The MF-2024 plant prioritizes precision and quality, utilizing a hardened steel die and nitrided steel extruder for optimal filament production. The PLC-based touchscreen control streamlines operations, while ceramic heating and water cooling ensure consistent temperature and filament quality. Designed for user safety and process reliability, this machine supports both virgin and recycled plastics, contributing towards sustainability and cost savings.

Exceptional Efficiency and Energy Savings

Engineered for performance, the MF-2024 delivers a high efficiency of 95%% and supports energy savings up to 15%% compared to conventional systems. Its centralized lubrication system reduces maintenance needs, whereas the robust three-phase electric drive sustains output speeds up to 220 m/min. The durable, powder-coated stainless steel construction ensures a service life exceeding a decade, making it ideal for continuous industrial use.

FAQs of Monofilament Plant:

Q: How does the MF-2024 Monofilament Plant maintain consistent filament diameter during production?

A: The MF-2024 utilizes a precisely engineered nitrided steel screw, five optimally controlled ceramic heating zones, and PLC-based automation to continuously monitor and adjust the extrusion parameters. Water cooling ensures rapid and uniform solidification, resulting in highly consistent filament diameters ranging from 0.15 mm to 1.5 mm.Q: What materials can be processed on this monofilament extrusion machine?

A: This plant is capable of processing both PP (Polypropylene) and HDPE resins. Additionally, it supports the use of recycled plastic materials, further supporting sustainable manufacturing and lowering raw material costs without sacrificing product quality.Q: When should routine maintenance be performed on the MF-2024 plant?

A: Routine maintenance should be carried out every six months as per the recommended maintenance interval. The automatic centralized lubrication system reduces manual interventions, and with spare parts readily available in stock, service interruptions are minimized.Q: Where can the MF-2024 Monofilament Plant be installed, and what are the ambient requirements?

A: This machine is suitable for installation in well-ventilated industrial environments where the ambient temperature is between 10C and 45C. The detailed installation manual provided ensures proper setup for optimal performance and safety.Q: What is the process flow for producing monofilament yarn on this machine?

A: The process involves feeding PP or HDPE granules into the hopper loader, melting them in the extruder, and shaping the molten mass through a hardened steel die. The monofilament is then rapidly cooled in a water bath, stretched, and wound onto bobbins. The entire operation is monitored and controlled via a touchscreen HMI and PLC system.Q: How does the MF-2024 ensure operator safety during operation?

A: Operator safety is prioritized with features such as an emergency stop button and overload protection. The touch HMI allows for remote operation, and full safeguard mechanisms are integrated into the control system to prevent accidents and ensure safe handling.Q: What are the main benefits of using the MF-2024 Monofilament Plant for manufacturers?

A: Manufacturers benefit from high efficiency (up to 95%%), reduced energy consumption, automated operation, and the ability to process recycled plastics. The robust construction, long service life, and comprehensive after-sales service guarantee a reliable investment for large-scale and sustainable production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in PP HDPE Monofilament Plant Category

HDPE Monofilament Plant

Price 2851000 INR / Unit

Minimum Order Quantity : 1 Unit

Usage & Applications : Yarn making, Monofilament thread, Brush Industry, Fishing Net, Agro Shade Net

Surface Finish : Other, Powder Coated

Weight (kg) : 3500 kg

Model No : HDPEMONO300

GST : 24ABTPJ5567H1Z7

|

|

JVM PLASTOMECH

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry